The Complete Guide to Felting Needles

Posted on

The Complete Guide to Felting Needles

What is a felting needle?

Felting needles are tools for matting together fibres, either synthetic or natural. For the rest of this guide, we will call that fibre ‘wool’. Felting needles are between 3” - 4” in length and made of metal.

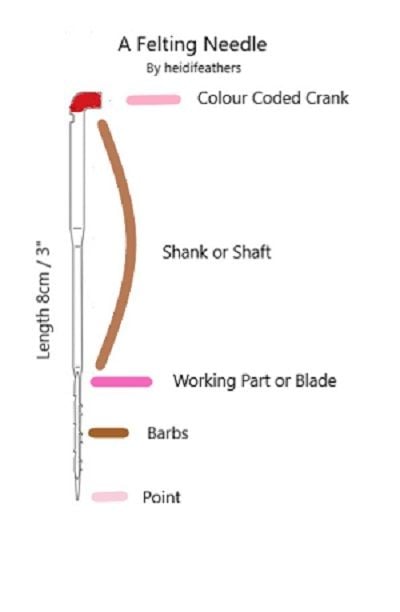

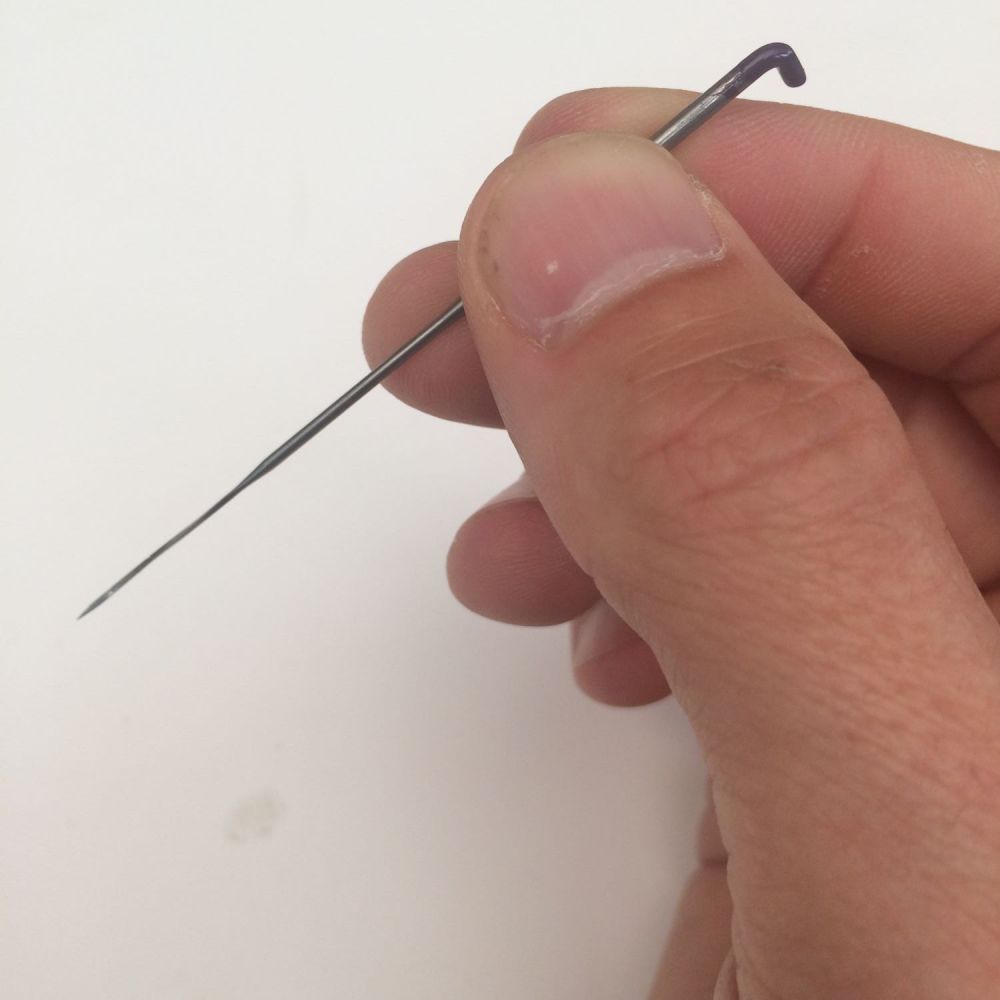

The felting needle has a bent top called a ‘crank’.

The top half of the felting needle is called the ‘shank’ or ‘shaft’. It has no working parts but creates length and strength to the needle.

The lower half of the shaft is cut into a blunt blade. The blade has two main designs, either a triangular blade which has three edges, or a star blade which has four edges.

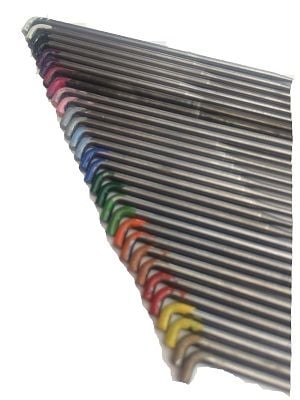

Heidifeathers felting needles are all made 3” in length, and the crank is 5mm in length, which allows them to fit into all felting handles.*

*Apart from handles designed to use ‘cut needles’ which are needles that only have the working blade and not the long shank.

What are the different types of felting needle?

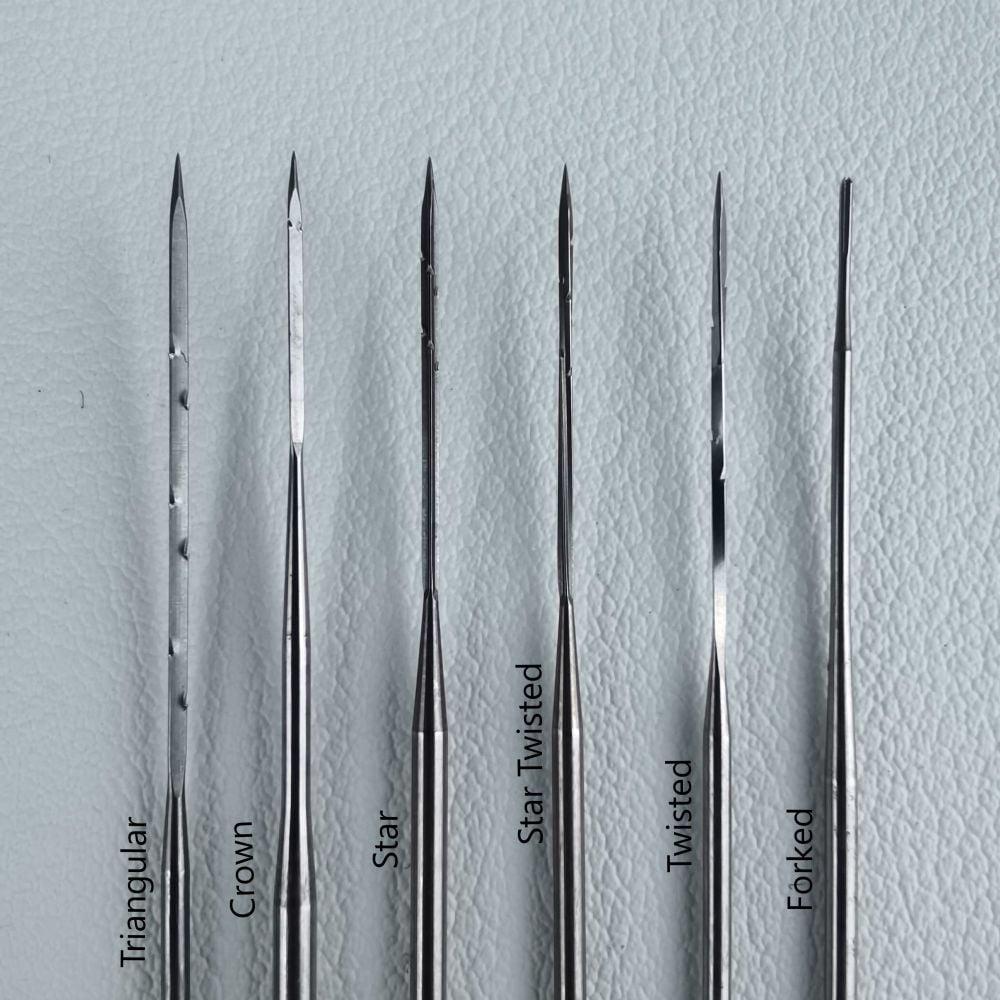

Firstly, there is the triangular needle, this has three sides on the blade.

The triangular needle can have a twisted blade, the needle is then known as a twisted or spiral needle.

Secondly, there is a star needle, which has four sides on the blade, creating a simple star shape.

The star needle can also have a twisted blade and this is commonly known as a star twisted or star spiral needle.

Finally, there is a forked needle. This has no blade. The working part is a tiny V shape at the point of the shaft.

Why use different types of needles?

Triangular needles are a good basic felting needle, they are multifunctional and come in a large range of sizes.

Twisted needles have a blade that distributes the barbs to cover a greater area, felting evenly, and faster than a triangular needle. They also make smaller entry holes due to the twisted blade and distribution of barbs.

Star needles have closer barbs nearer the tip of the needle. This means you use less effort to work the needle in the felt, and they work with more impact, making them faster to felt with.

Star twisted needles hold properties of both the star and the twisted needle.

Forked needles are used for pushing fibres into something as opposed to felting, so can be used to add fur or hair.

What are the different sizes or gauges of felting needle?

Felting needles have different sizes, known as gauges. The gauge is the thickness of the blade, which is the working area.

Felting needles come is sizes from 19 gauge to 46 gauge. Needle gauge is called G, i.e. 42g.

The triangular shape needles have the largest range of sizes.

Here at Heidifeathers we supply needles from gauges 32G – 46G. Like knitting needles, the higher the number, or gauge, the thinner the needle. The smaller the gauge, the thicker the blade.

To start felting the wool, it is advisable to use a needle with large and multiple barbs, so the thicker lower gauge needles are best. Then change up to the thinner, higher gauge needles, so a mix of needles is helpful.

Below is a table to show the relative sizes of felting needles, there gauges and availability in those sizes.

Why are felting needles barbed?

On the blade of the needle there are notches cut out, these are called barbs they are usually randomly placed on the edges of the felting needle blade.

This random spacing means the notches are in different places on each edge, making the needle less prone to breaking, as having the barbs in the same place on each edge will create weak points on the needle blade.

The number and size of the barbs on the needle are related to the size of the needle. See our needle guide for barb numbers on Heidifeathers needles.

The crown triangular needle has regularly spaced tiny barbs all at the same place 3 mm’s from the point.

Although the tip of a felting needle point is sharp, the working parts are the barbs.

The barbs work by wool getting caught in the barbs as you push the needle into the wool. The more you push the felting needle into the wool, the more the fibres tangle, and so felt together.

Felting the wool with the needle will make the wool feel firmer. The more you work an area with a felting needle, the more compressed the wool fibres become, thus shrinking the size of the wool where you are needling. The barbs and this process enable you to shape the unspun wool with the felting needle.

Safety when needle felting

To needle felt safely with felting needles, you need a surface which the needles can go into with ease such as a foam or wool mat.

Finger and thumb guards are useful especially when you are new to the hobby, or working with small amounts of wool.

Felting needles are brittle and break easily. To reduce snapping, do not put a lot of pressure on the needle.

Never bend them or twist them when in the wool. The needle should penetrate the wool in a straight in, straight out motion. Do not move the wool when the needle is in it.

Always concentrate on what you are doing. Felting is better with the radio on rather than watching t.v.

How long do needles last?

Felting needles do blunt down with use. After each project completed, compare your used needle with a new one. If you can't tell the difference, it is good for your next creation! If there is a noticeable difference, decide whether it is worth keeping the needle and having to work harder to get the next item felted or changing it for a sharp new needle.

Which felting needle gauge to use when?

Please see our needle felting guide and key for details of all needles colour codes and uses

Best starting felting needles

Use a lower gauge number needle such as a 32G or 36G or a hybrid needle like a 38G star twisted. See our coarse mix

Best joining felting needles

A lower gauge needle such as a 36G will quickly and effectively push the wool from the new joining part into the main body, remember to leave a pinch of loose fibres to help this process.

Best fluffing felting needles

To create fluff like the tail of a bunny or fur of a bee, consider using a reverse felting needle to pull the wool fibres out. A 40G needle will create subtle fluff, while a 36G needle will quickly create a more substantial effect.

Best felting needle for fine detail

To add fine details a higher gauge number needle is best, such as a 40G or a 42G needle, as these needles can work with a few wisps of wool to create fine details.

As the needle gauge goes higher, the barbs on the needle get smaller and there are less of them, so pull less fibres into the felted piece. See our fine mix

Best felting needle for finishing

Changing needles when finishing a piece can reduce pockmarks from other needles, pull in loose fibres and create a firm surface. Use higher gauge needles such as the 40G, 42G either triangular, twisted or crown or a combination of all three. See our smooth finish mix

Best felting needle for working or midway

After a period using starter needles, they will not comfortably enter the wool, at this point you need to change to a higher gauge needle such as a 38G or 40G gauge. See our medium mix

If you use a star or twisted needle, the midway felting will be faster. Depending on the size of your project, you can choose a multi needle tool to work with, such as a wooden 4 or 6 needle handles.

When your needle will not enter the wool with ease, move to a higher gauge needle.

Best felting needle when adding fur

The needle does not need to felt the item, so a mid to high gauge needle or a crown needle, are good, so a 38G or 40G.

Making holes

A felting needle can make a dip, but if you want a hole to add a glass eye for example, you want to use a felting awl or a sewing needle. Simply poked in and twisted to create a hole, the hole will close again if nothing is added into it.

Best needle when working with wire

When working around wire you need to use the upmost care, you can often twist and smooth the wool on with your fingers. This uses the lanolin in the wool and the heat and friction of your hands to felt the wool before using a needle.

Using a stronger needle such as a 38G star needle will reduce likelihood of breaking and working with care and attention when stabbing to not hit the wire with force.

When to change from one gauge needle to another

When the needle is struggling to enter the wool, or leaving large marks, change it for a higher gauge needle.

If the needle is taking too long to felt the wool, change it for a lower gauge needle.

When the needle is not gaining the desired effect, experiment with different types or gauges until you find one that works better on that job.